As global trade tensions rise and import tariffs climb to levels not seen in years, one American business owner finds themselves at the center of a high-stakes experiment: will consumers pay more for products proudly labeled “Made in USA”?

The question is no longer theoretical. For many small and mid-sized businesses, tariffs on imported raw materials, components, and finished goods have reshaped cost structures almost overnight. Some have moved production overseas in search of lower costs. Others, however, are choosing a different path—bringing manufacturing home, embracing domestic production, and betting that customers will value American-made goods enough to absorb higher prices.

This is the story of how tariffs are forcing business owners to rethink strategy, how “Made in USA” has become both a marketing promise and a financial risk, and what this moment reveals about consumer behavior in a changing global economy.

Tariffs and the New Cost Reality for Businesses

Tariffs are essentially taxes on imported goods. When governments impose them, the goal is often to protect domestic industries, reduce reliance on foreign supply chains, or gain leverage in international trade negotiations. But for business owners who depend on imported inputs, tariffs can feel less like protection and more like punishment.

For years, globalization allowed companies to source materials and labor at the lowest possible cost. Components came from Asia, assembly took place in multiple countries, and final products were shipped across oceans. This system kept prices low and profit margins healthy.

Tariffs disrupt that equation.

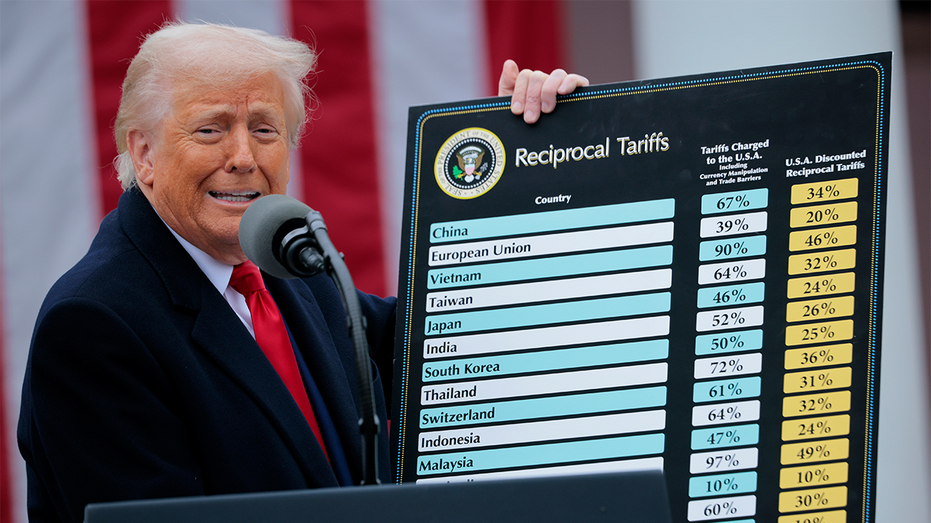

A business owner importing steel, electronics, textiles, or machinery may suddenly face cost increases of 10%, 25%, or more. These added expenses force difficult decisions: absorb the costs and accept lower margins, pass them on to customers, or completely redesign the supply chain.

For some, the only viable option is to shift production to the United States—even if it means higher labor and operating costs.

The Decision to Go “Made in USA”

Choosing to manufacture in the U.S. is not just a logistical change; it is a philosophical one. Domestic production often means higher wages, stricter regulations, and more expensive real estate. On paper, it can look like a losing proposition.

Yet many business owners see advantages beyond cost.

Producing in the U.S. offers:

-

Greater control over quality

-

Faster turnaround times

-

Reduced shipping delays

-

Fewer geopolitical risks

-

Stronger brand credibility

For one business owner now facing steep tariffs, the choice came down to survival. Imported components had become so expensive that the cost difference between foreign and domestic production had narrowed significantly. If prices were going up anyway, why not invest in American manufacturing?

The decision also opened the door to a powerful label: “Made in USA.”

The True Cost of American Manufacturing

Despite its appeal, domestic manufacturing is far from cheap. Labor costs in the U.S. are among the highest in the world. Compliance with environmental, safety, and labor regulations adds additional expenses. Healthcare, insurance, and taxes further raise overhead.

For small businesses especially, these costs can be overwhelming.

Unlike large corporations, small manufacturers lack economies of scale. They cannot easily negotiate bulk discounts or spread costs across massive production volumes. Every increase in cost directly affects pricing.

As a result, products made in the U.S. often cost significantly more than imported alternatives. A product that once sold for $50 might now need to sell for $70 or $80 to remain profitable.

That price gap is where the real test begins.

Will Consumers Pay More for “Made in USA”?

The idea that consumers support American-made products is deeply ingrained in national identity. Surveys often show that people say they prefer domestically produced goods. They associate them with better quality, ethical labor practices, and support for local jobs.

But stated preferences do not always match purchasing behavior.

At the checkout counter, price still matters. Many consumers operate under tight budgets, especially during periods of inflation. When faced with two similar products—one imported and cheaper, the other American-made and more expensive—the decision is rarely simple.

Some customers are willing to pay a premium for:

-

Perceived higher quality

-

Durability and craftsmanship

-

Ethical sourcing

-

Patriotism or economic nationalism

Others, however, simply cannot afford to.

For the business owner testing the “Made in USA” strategy, this uncertainty is the biggest risk. Raising prices could strengthen brand identity—or drive customers away.

Branding “Made in USA” as a Value Proposition

To succeed, American-made products must offer more than a flag on the label. Smart business owners understand that “Made in USA” works best when paired with a compelling story.

That story often includes:

-

Transparency about sourcing and production

-

Emphasis on skilled labor and craftsmanship

-

Commitment to sustainability

-

Investment in local communities

When customers understand why a product costs more, they are more likely to accept the price.

This shift requires businesses to move from cost-based competition to value-based competition. Instead of asking, “How can we be the cheapest?” they ask, “How can we be worth more?”

For many, this means redesigning marketing, improving customer education, and building emotional connections with buyers.

The Role of Tariffs in Reshaping Supply Chains

Tariffs have accelerated trends that were already underway. Even before trade barriers increased, businesses were reevaluating global supply chains due to disruptions, delays, and rising shipping costs.

Recent years exposed the fragility of just-in-time manufacturing. Factory shutdowns, port congestion, and geopolitical conflicts left shelves empty and production lines stalled.

Domestic manufacturing offers resilience.

By producing closer to home, businesses reduce dependency on distant suppliers and unpredictable global events. While costs may be higher, reliability and speed improve.

For some business owners, tariffs served as the final push to make a transition they had long considered but never fully committed to.

Small Businesses vs. Large Corporations

Large corporations are better equipped to handle tariffs. They can:

-

Absorb costs temporarily

-

Shift suppliers across countries

-

Negotiate exemptions

-

Leverage political influence

Small business owners rarely have those options.

When tariffs hit, they feel the impact immediately. A single price increase can threaten cash flow. A delayed shipment can halt operations. Unlike multinational companies, small firms cannot simply move factories overnight.

For these businesses, going “Made in USA” is not a political statement—it is a survival strategy.

But survival depends on whether customers are willing to follow.

Consumer Psychology in a High-Price Environment

Consumer behavior is shaped by more than price alone. Trust, identity, and values play critical roles.

Some consumers see buying American-made products as an investment in:

-

Domestic jobs

-

National resilience

-

Ethical labor practices

Others view it as a luxury reserved for higher-income households.

The challenge for business owners is to expand the audience willing to pay for domestic products. This may involve offering tiered pricing, smaller product sizes, or subscription models that make higher prices feel more manageable.

Clear communication is essential. When customers understand that higher prices reflect fair wages, safer working conditions, and local economic support, the purchase becomes more meaningful.

Risks of the “Made in USA” Bet

Despite its advantages, the strategy is not without risks.

If consumers reject higher prices, businesses may face:

-

Declining sales volumes

-

Inventory buildup

-

Reduced cash flow

-

Pressure to cut costs elsewhere

There is also the risk of being undercut by competitors who continue importing cheaper goods, especially in price-sensitive markets.

Additionally, not all products benefit equally from domestic branding. Commodities and low-differentiation items are harder to sell at a premium, regardless of origin.

Business owners must carefully assess whether their product category, customer base, and brand positioning support the “Made in USA” approach.

A Broader Economic Experiment

Beyond individual businesses, this moment represents a broader economic experiment. Policymakers argue that tariffs will revive domestic manufacturing and create jobs. Critics warn that they raise prices and burden consumers.

The reality likely lies somewhere in between.

Tariffs may encourage some production to return to the U.S., but they also expose the true cost of domestic manufacturing. The question is whether the market can sustain those costs without sacrificing competitiveness.

Business owners on the front lines are testing that theory in real time.

The Future of American-Made Products

Looking ahead, the success of “Made in USA” may depend on innovation as much as ideology. Automation, advanced manufacturing, and new technologies could help offset higher labor costs and make domestic production more competitive.

Government incentives, tax credits, and workforce development programs may also play a role in supporting businesses willing to manufacture locally.

For now, however, the burden largely falls on entrepreneurs and consumers.

Conclusion: A Test of Values, Not Just Prices

For the business owner facing steep tariffs, the move toward “Made in USA” is both a gamble and a statement. It tests not only market demand but also consumer values.

Will people pay more to support domestic jobs?

Will quality and transparency outweigh lower prices?

Will American manufacturing find a sustainable place in a globalized economy?

The answers are still unfolding.

What is clear is that tariffs have forced a reckoning. They have stripped away the illusion of cheap, frictionless global trade and exposed the real costs behind everyday products.

In this environment, “Made in USA” is no longer just a label. It is a challenge—to businesses, to consumers, and to the economic system as a whole.

Read Also: Keep your face towards the sunshine and shadows will fall behind you

Watch Also: https://www.youtube.com/@TravelsofTheWorld24

Leave a Reply